Crime scene and forensic analysis is a critical aspect of law enforcement, involving identification, collection, documentation, and preservation of physical and biological evidence. One missed detail could disrupt the entire investigation. With only one opportunity to properly process the crime scene, investigators should be well-equipped with the appropriate tools.1

Although there is a great emphasis on collecting and processing evidence, there is also an overlooked aspect of forensic investigations: risk. Processing complex scenes could take hours, which increases the risk of scene contamination and exposure to hazards while on scene.2 With the help of forensic tools—such as diagramming software, spectrometers, and even special fabrics—these risks are mitigated and minimized as investigators work to find items of evidentiary value.

Risks to Officers

Officers at crime scenes are exposed to a vast array of hazardous materials and substances seen or unseen, and these hazards have changed substantially over the last 50 years. Luckily, the approaches and analytical tools available to aid in forensic analysis and prosecution have changed, too.3

“With the emergence of highly toxic synthetic drugs, such as fentanyl, fentanyl analogs, and xylazine, it is critical for officers to be able to identify low concentrations of drugs in the presence of cutting agents or other drugs,” said Joe Gallo, 908 Devices’ product marketing manager.4 That is exactly what the MX908 handheld mass spectrometer allows investigators to do. The multi-mission device can identify trace levels of drugs, as well as chemical warfare and pharmaceutical-based agents, explosives, and toxic industrial chemicals.

The MX908 has enabled officers to access trace evidence that was previously not possible or too difficult to detect. By using high-pressure mass spectrometry, the MX908 analyzes a sample and compares its mass spectrum to a target list. If there is a match, the device returns a simple alarm to the user in under one minute. This process does not require sample preparation, meaning that users can receive a result from residues on the outside of a package without exposing themselves to potentially toxic substances.

When officers must handle potentially harmful chemicals and unknown substances, Mystaire’s products ensure they remain safe during investigative work. For 60 years, Mystaire has been at the forefront of occupational and environmental safety with a focus on filtration-based solutions to provide air pollution control products for laboratories. The company’s full line of ductless solutions provides protection from illicit narcotics; toxins; and standard chemicals, dyes, and powders used to treat and develop latent prints. The Advanced CA Chamber is designed to develop latent fingerprints on nonporous items, while the Latitude Fentanyl Filtered Hood protects law enforcement professionals from exposure to harmful substances.

The Advanced CA Chamber is currently used by local, state, federal, and international agencies to process items of evidence and determine if any fingerprints are present for collection. To create an ideal environment for processing latent prints, the vaporization of the cyanoacrylate within the chamber is accelerated while relative humidity is generated. The air within the chamber continues to circulate to evenly distribute the glue fumes and humidity. Once the development cycle has been completed, all cyanoacrylate fumes are cycled through an activated coconut shell carbon filter to prevent officer exposure to the potentially harmful fumes.

Mystaire’s Latitude Fentanyl Filtered Hood utilizes several filters to capture particulates that are released into the air. The hood’s horizontal airflow pulls airborne particulates directly toward the rear wall of filters known as the Saf-T Zone. The first filter is an electrostatically charged pre-filter, which is followed by a high-efficiency particulate air filter. Once air passes through these two stages, there is a third filtration process that is leak tested and certified. A fourth layer can be added if there is concern for vapors in the evidence.

“Our products truly aid the law enforcement community as they collect, preserve, and attempt to identify the ‘who’ that committed the crime,” said Mystaire President Mark Leath.5

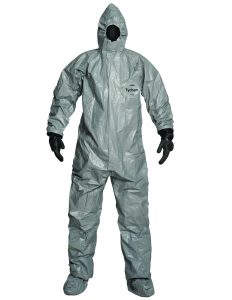

The potential for exposure to hazardous chemicals is not limited to the laboratory. DuPont’s Tyvek and Tychem fabrics are the foundation of a line of protective garment solutions. Invented in the late 1950s, Tyvek was discovered during an experiment to create a barrier to prevent moisture from seeping into homes. Due to its breathability and durability properties, DuPont adapted Tyvek as a protective garment material. It is a nonwoven substrate made of high-density polyethylene fiber that is flash-spun and bonded together. This unique manufacturing process offers investigators protection against small hazardous particles while remaining air permeable and durable.

Tychem 6000 fabric is made by adding a chemical resistant barrier to the outside of the Tyvek fabric.

Risks to Scenes

Contamination of a crime scene may seem inevitable. The nature of the crime, how long the scene sat before processing, and even weather conditions present challenges to accurate scene documentation.

Although there are multiple factors that could contaminate evidence at a crime scene, agencies could have control over what their own personnel introduce.

DuPont has also taken that into consideration while developing their Tyvek and Tychem garments. “Both Tyvek 400 and Tychem 6000 are used by law enforcement in applications where protection of environmental integrity (crime scenes) and officer protection (contaminated environments) are critical,” said DuPont’s government sales leader, Dan Bowen.6

Tyvek is an ideal material to reduce investigator contamination for two reasons: (1) what it is made from and (2) what it does. Its high-density polyethylene fibers provide excellent particle holdout; therefore, any materials that may be introduced by investigators are kept inside the suit, minimizing the potential for crime scene contamination.

With FARO Technologies’ 3D laser scanning technology, investigators will no longer need the time-consuming process of hand measurements and sketching or complicated manual forensic calculations, which were often prone to human error. The new technology enables rapid scene processing, allowing law enforcement agencies to minimize disruptions to crime scene analysis.

The FARO Focus Premium Laser Scanner has modernized crime and crash scene documentation by providing the ability to capture an entire scene in 360 degrees to create a 3D point cloud within minutes. Alongside distance measurements, the scanner also captures high-resolution photos. The images are overlaid onto the point cloud, providing texture and color to the model.

The data from the laser scanner is integrated into FARO Zone forensic and diagramming software, where investigators can digitally analyze the scene to prepare documentation for court. FARO Zone allows for basic and complex 2D and 3D diagramming, which creates accurate visual representations of crime scenes. The software is also equipped with detailed animations that bring static scenes to life for better understanding in courtroom presentations.7

When evidence has been contaminated or has been split into tiny fragments, Othram may be able to step in. “We come into play when [Combined DNA Index System] tests don’t lead to results,” said Othram Chief Development Officer Kristen Mittleman. “Without forensic grade genome sequencing, many of these cases are permanently stuck or unsolvable.”8

Othram has a full in-house forensic lab and research lab to help determine the probability of success for a case. Within each profile are hundreds of thousands of markers. By sequencing so many markers, distant relationships will appear when uploaded to genealogical databases, which could assist in the identification process. If the company is working on a contemporary case, a profile can be built within a few days; otherwise, it takes about six weeks to complete a profile. “Each time we have delivered back a successful lead, we’ve created a ‘truth set,’” said Mittleman. “That’s why we do all of it in-house. So that we can compare back to it, and we can say with certainty that we know we can help in this next investigation because we’ve built a similar profile before.” When the company places evidence from agencies on hold, a mock case is developed in the research lab to continue to work through the processes until analysts are certain they can work with that type of evidence.

Othram’s electronic record can be easily printed, and standardized reports have been utilized across the United States for use in the courtroom. If an agency goes to court, Othram will provide an individual to testify if needed.

The company is aiming to create standards and metrics for the field to earn law enforcement’s trust in the new technology. “We hope that we would set so much infrastructure over the next few years that every case that has DNA will have a chance to be identified through this type of DNA testing,” said Mittleman. As of October 2023, Othram has successfully completed 106 public identifications, which is only a fraction of the cases that have been completed over the year that must remain confidential.

Conclusion

While some risks that occur during crime scene processing may seem unavoidable, it is imperative that investigators are equipped with the appropriate tools that are designed to avoid or minimize some of these problems. d

Notes:

1Richard English, “Who Is Processing Your Crime Scenes? Law Enforcement’s Missed Opportunity,” Police Chief Online, November 8, 2023.

2FARO Technologies, email interview, November 1, 2023.

3Dan Bowen (government sales leader, DuPont), email interview, October 27, 2023.

4Joe Gallo (product marketing manager, 908 Devices), email interview, October 18, 2023.

5Mark Leath (president, Mystaire), email interview, October 26, 2023.

6Bowen, email interview.

7FARO Technologies, email interview.

8Kristen Mittleman (chief development officer, Othram), phone interview, October 16, 2023.

|

SOURCE LIST |

|